Are you a designer or creator who frequently utilizes a laser cutter? Perhaps you operate a laser cutting service or are involved with an educational institution where these devices are employed. Those acquainted with laser cutting are familiar with the challenges: subpar quality materials that prove difficult or impossible to cut, often available only in large quantities, and accompanied by high delivery costs.

It all begins with selecting the finest materials. Not every sheet material is suitable for laser cutting and engraving. The adhesive in plywood and MDF doesn't always respond well to the laser cutter. A single knot in the sheet, and you find yourself restarting the process. Such situations frequently lead to frustration, which is entirely avoidable.

At Lasersheets, we possess a comprehensive understanding of sheet materials that are conducive to laser cutting and are commonly used. Drawing from our 12 years of experience as a laser cutting service (in collaboration with our sister company, Snijlab), we are eager to share our knowledge and insights with anyone engaged in laser machine engraving and cutting.

If you're a designer, you can explore our list of 'best practices in terms of material use' here. Working in a Makerspace, Fablab, or a school? These materials might be essential additions to your inventory. Recognizing that each target group is unique, you can tailor your selection accordingly. To facilitate a quick start, we're sharing our top 10 materials for laser cutting here.

The best materials for laser cutting and engraving

These 10 sheet materials for laser cutting and laser engraving all have different characteristics, which makes them suitable for different purposes. Some are soft and flexible, others are sturdy and modern and others are natural and stylish.

Read more about our 10 top products of the moment.

1. Birch plywood

Birch plywood is an excellent wood for the laser cutter. It is a hard, strong type of wood, with a beautiful, subtly visible grain. The typically attractive and natural appearance of this material is very recognizable. That is why it is widely used.

When birch plywood is assembled, multiple layers are glued together in a crosswise fashion. It's worth noting that the sheets exhibit increased stiffness along the midrib direction. Our birch plywood is virtually free of knots, minimizing potential issues during processing.

Ensuring that the glue used is suitable for laser cutting is crucial. The varieties typically found in hardware stores may not meet this criterion. You'll notice this when your laser struggles to penetrate and leaves charred edges.

Our birch plywood is specifically crafted for laser cutters, featuring the appropriate laser-cuttable glue. This ensures swift laser cutting with aesthetically pleasing golden brown edges that don't transfer. The wood is sourced from sustainably managed forests in Scandinavia. Additionally, the most commonly used thicknesses, 3mm and 6mm, are FSC® certified, highlighting our commitment to responsible forestry practices.

2. MDF

MDF is also a favorite material for many laser cutters. It consists of pressed and glued wood fibers and not of different layers, as is the case with plywood. The advantage of MDF for laser cutting is that it is homogeneous, which means that the material is equally thick and hard everywhere. That makes it a predictable and enjoyable material to work with when you laser cut it.

Another advantage of MDF is its cost-effectiveness. It is extensively utilized for prototypes and items that require additional finishing. Explore our MDF sheets designed for laser cutting; some come pre-finished, such as those featuring a veneered oak top layer. This provides additional options for achieving a desired aesthetic in your laser-cut projects.

The MDF boards with a thickness of 3, 4, 6 and 9 millimeters from our range are also FSC® certified. Where possible, we always look for the most sustainable option. For model making, or laser cutters with lower power, we also have 1mm thick MDF and 2mm thick MDF . Of course, all our MDF can be used without any problems in the laser cutter and is made with the right glue.

3. Matte acrylic

Acrylic is a versatile plastic that can be supplied in various colors and designs. Matt acrylic in particular is very popular with us, due to its modern and stylish appearance. The great thing about acrylic is that it is UV-resistant and colourfast. So you don't have to worry about discoloration, even if you use it outside.

With our matte acrylic you can laser cut everything, from facade advertisements to models to hobby projects. No finishing is necessary.

4. PE rigid foam

Our foam types can also be processed in the laser cutter. PE rigid foam is slightly harder than an average mattress. That is why it is widely used as the lining of suitcases and toolboxes, as well as for logos and layered sculptures. Also useful to know: PE rigid foam is waterproof and resistant to chemicals. Therefore, it is a good choice for use in workshops.

PE rigid foam panels are offered in various thicknesses and sizes. By precision cutting specific shapes into the foam, you can establish secure storage spaces for your tools, musical instruments, or other delicate items. Additionally, if desired, you have the option to engrave text or a logo adjacent to these custom-cut spaces.

5. Crystal clear acrylic

Acrylic that , unlike our matte acrylic discussed earlier, allows light and visibility to pass through. Crystal clear acrylic is also UV-resistant and colourfast. Outdoor use is therefore no problem. It is also a relatively stiff material, making it versatile and widely applicable.

Because you can see through crystal-clear acrylic and because it is weather-resistant, it is often ordered from us for facade advertising, logos and front panels. Also use it instead of glass, for example in your children's playhouse, for a safer choice.

6. PP (Polypropylene)

In contrast to stiff acrylic, PP is very flexible. It is supplied as a thin plastic film. It is unique because it can be folded. The surface has a light structure. You have undoubtedly come into contact with this material, because it is used, for example, for file folders and protective covers.

We offer PP in all kinds of colors and despite its flexibility, it is also quite tough and scratch resistant. By cutting it to size with the laser cutter and engraving folding lines, you can make your own foldable box or lampshade.

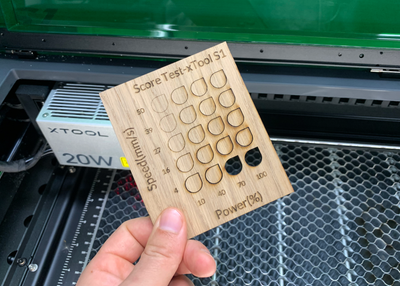

7. Bamboo

Bamboo is a fast-growing and therefore sustainable wood for the laser cutter. These bamboo panels are solid, unlike plywood. They are made by gluing strips of bamboo together. If you bend it along the grain, you will notice how stiff and tough the material is. But be careful, it is also susceptible to breakage across the grain.

Even though bamboo is not the easiest material to work with, it is a sustainable material with a unique and warm appearance. For example, use it to make housings or as front panels for your kitchen cabinets.

8. Black MDF

You have already read about our uncolored MDF, but did you know that there are also MDF boards that are already pre-colored? In this case it is black MDF and finishing is no longer necessary. The advantage is that our sheets are tinted through and through and have not just been given a top layer. This makes scratches and other damage much less visible. Of course, just like standard MDF, it is also homogeneous and easy to use.

Black MDF is somewhat stronger and considerably heavier than standard MDF. Both sides look the same. It is colourfast, but not waterproof. So first give it a coat of paint if you want to use it outside. Our black MDF can be used in all kinds of fields, from hobby to professional, and is available in several thicknesses.

9. Acrylic gold mirror

Look at our acrylic with a gold mirror and you will clearly see how versatile this plastic is. In this version it resembles a standard mirror with a beautiful golden shine. These mirrors have no wrinkles and reflect the mirror image perfectly. You can laser cut them in all kinds of shapes, which can create a beautiful effect.

Cut this acrylic with gold mirror into the right shape and you turn it into much more than just a unique mirror. It is also ideal for displays and billboards, lamps and other lighting. And because it is acrylic, you can also use it outside without any problems.

10. Poplar plywood

We conclude the list of our 10 best materials for laser cutting with poplar plywood . You can immediately recognize this wood for the laser cutter by its light color and low weight. Poplar is a soft type of wood and therefore less strong and stiff than birch plywood.

The advantage of the lower weight is that the sheets can be supplied with higher thicknesses. It is widely used in model building. Do you want to use it outside, for example as a sign? Then make sure you first finish it properly and make it weatherproof.

The ideal materials for your laser cutter

What is the optimal material for your upcoming laser cutting endeavor? We consistently advocate for selecting high-quality materials. This ensures a safe cutting process, free from knots, with clean seams and edges emerging seamlessly from your laser cutter, devoid of any damage.

When you place an order with us, rest assured that you'll receive materials perfectly suited for laser cutting – it's our expertise! We accommodate all orders, whether in small quantities or bulk, and we offer postal delivery. All our materials meet stringent quality standards.

Anyone with a laser cutter can contact us, so take a look at our extensive webshop or contact us for further advice.