You want to make beautiful products with your laser cutter, right? Or you want to offer your customers or students good quality materials. But of course at the lowest possible cost!

The first thing you might look at is the lowest possible square meter price. And that makes sense, that is indeed the starting point. But there are more costs that are incurred around your materials. The good news is that you can save a lot if you are aware of the different coss and how you can influence them.

In this blog you can read about all the factors that influence your purchasing expenses for laser materials. We are happy to help you purchase as smartly as possible. And with that you can save money!

(To a large extent, this blog also applies to workshops that use our materials in ways other than with lasers, for example for CNC milling or furniture making or model making)

Lets start with volume discounts

If you buy more at the same time (large print run), the square meter price drops. This is also known as volume discount (or volume discount). This discount can add up to 20% and even more. So it is often worthwhile to order a little more at once. In our webshop you will find a table with volume discounts for each material. The discount is automatically applied as you place the product in your shopping cart.

Shipping/Transportation costs

Because you need quite specific materials for laser cutting, you usually can't just buy them at the hardware store. The best materials are actually only available from wholesalers (and of course from Lasersheets!). At wholesalers you often pay considerable transport costs that can amount to 250 euros per delivery. That is not surprising, because the materials are often delivered on large sheets that take up a lot of space during transport. Because you often use very different materials for laser cutting ( wood , plastic , cardboard , etc.) you will end up with different wholesalers who of course all charge separate transport costs. So try to order as much as possible from one supplier, and as much as possible tailored to your machine. This makes a difference in transport costs, which translates directly into the costs per m²

Storage costs

If you buy in bulk you have to store material until you use it. You can quickly estimate the costs you pay for storage by multiplying the floor space of your cabinets by the rental costs per m². We also know a lot of workshops where the storage does not have a fixed location, but is often moved. How often do you move a material if it has been in your workshop for a year? How much material is damaged in that period and do you have to write it off? What do the cabinets in which you store your material cost? You understand; materials that are lying still also cost money. So while buying in bulk has benefits, it's important to strike the balance. When purchasing large quantities, consider carefully: how long will it take before I have used all the material and how much will I incur during that period? Does that outweigh the price advantage of the larger purchase?

The right materials

What is a workshop without material in stock? You don't want to have to order separately for each project, so you probably have some sheet materials lying around. It differs for everyone which materials these are exactly, but in general there are still runners and exotic materials. And too many exotic materials is usually not a good idea; they often lie on the shelf for a long time, resulting in high storage costs (see above). So make sure you know which materials are your runners and stock up on the right materials . This saves you costs. Don't know what the runners are or what your users would like? From our 12 years of experience, we have already made a shortlist for you of what the general runners are.

Suitable for laser cutting

It happens a lot; you have purchased a material but it cannot be lasered properly. your laser won't cut all the way through, or the edge will burn and turn ugly. That's a shame, because your project can't continue and you can't return the material.

Not all materials can be laser cut or engraved just like that. With plywood, for example, it is very important which type of glue is used. Many glues burn instead of being cut, blocking the laser beam.

Plastics come in a huge number of types and variants. A large part of it is not easy to cut or even toxic and harmful to your machine. You have to be quite experienced to see the differences by eye. Did you know, for example, that the transparent sheets that you see in the hardware store cannot be laser cut at all? If you were to get through it with your laser at all, the edges would burn brown and produce a lot of smoke. It is namely PC, polycarbonate. That is a thermoset and not suitable for laser cutting. If you don't want any surprises, choose materials that have been specially tested and are guaranteed to be easy to laser cut .

Outage costs

“Outage” or “production downtime” are products that have gone wrong during production. They have 'fallen out' during the manufacturing process and must be thrown away. Downtime hurts double, because you have to throw away the used material and the work has to be done again. A piece of failure effectively doubles your purchasing costs for that product/project.

It is therefore important, when you laser cut something, to ensure that it goes right the first time. And in that, one material is not the other. A good example is plywood. Poor quality plywood contains internal knots. You can't see them on the surface, but your laser beam can't cut through them. Now imagine that you have a large sheet of wood in your laser and you cut a beautiful design out of it in a few hours, and then you hit an internal knot.. Your entire work piece is often damaged beyond repair. In the case of your own work, you can sometimes hide the damage with finishing. But if you deliver customer work, you will have to throw the part away and start over.

This is where good materials can make you real money. And why it's worth investing a little more in plywood that is virtually knot-free.

Quality

More generally, high quality almost always leads to a lower price in the long run. As we just explained, good quality can save you a lot of cost and effort during production. But a material that lasts longer is of course always cheaper than the same material that has to be replaced sooner. Moreover, you put less burden on the planet!

Become a laser expert!

Finally, a few additional tips:

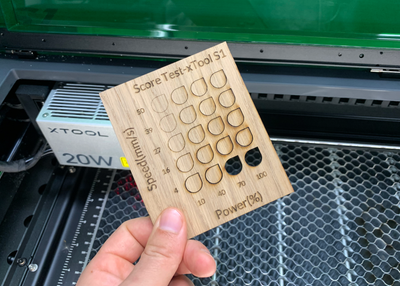

- Keep a log of your laser settings for each material. That saves you test material and waste.

- Keep the lenses of your laser cutter clean. A dirty lens can absorb up to 30% of your laser power, causing your project to fail and your material to be wasted.

- Benchmark your laser regularly and adjust your settings: Determine the maximum speed of your laser in 3mm MDF and regularly test whether you can still achieve that speed. Do you have to slow down the machine much to cut through? Then the power of your laser beam has decreased. This may be due to dirty lenses or mirrors, for example, or your machine needs to be adjusted. MDF is a good benchmark material because it is consistent and economical.

- Use good nesting software to get as many pieces out of your record as possible.

As you can see, there are many factors to take into account when purchasing sheet material. Our goal is to make it as easy as possible for you by offering the best materials for your laser cutter all in one place.