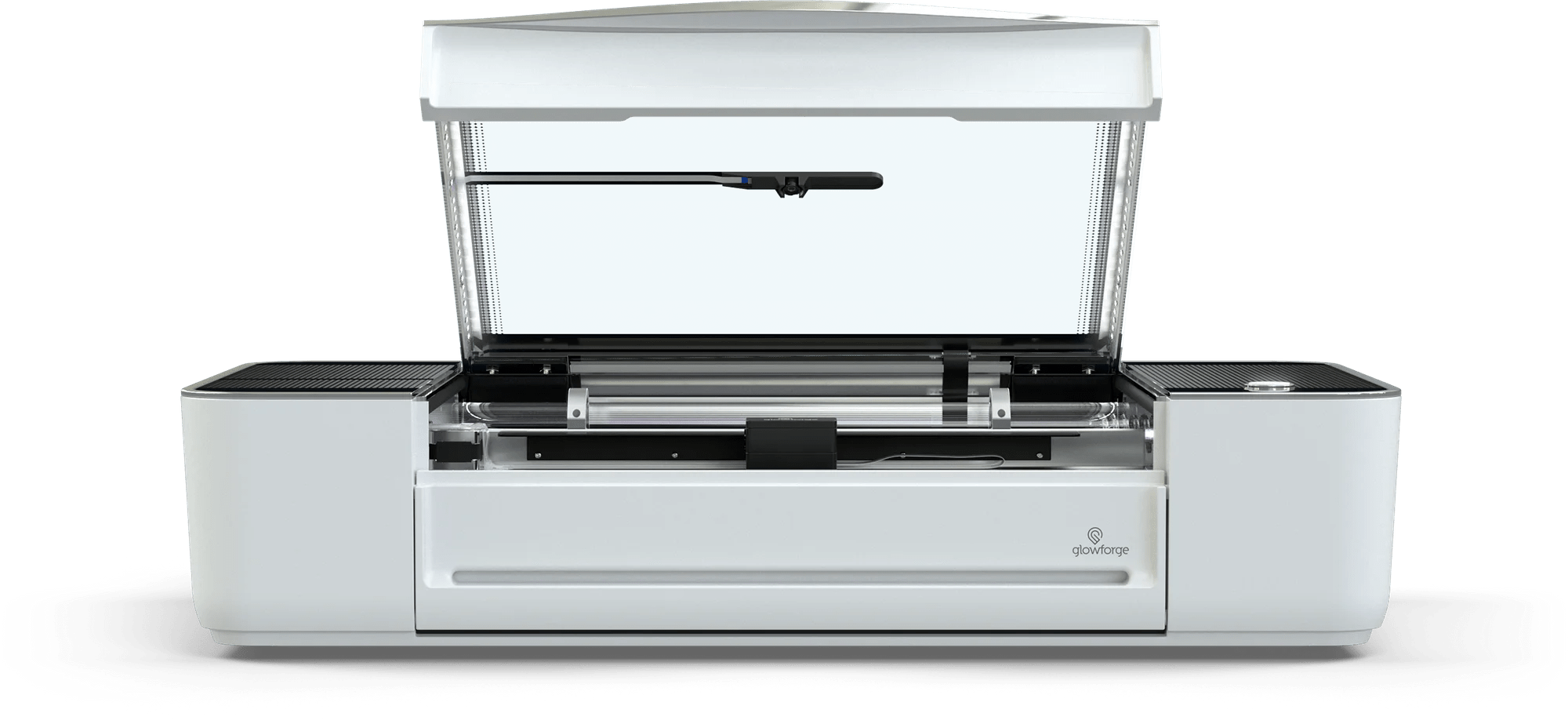

What is the Glowforge?

The Glowforge is often referred to as a laser printer, but in reality it is a laser cutting and engraving machine. With its compact size it is smaller than many other laser cutters, making it a perfect fit for smaller studios. Moreover, the glowforge is user-friendly and easy to learn. It is not surprising that it is one of the most popular lasers of the moment.

The Glowforge stands out with its web connectivity, allowing easy control from your browser. Basic use is free after the initial purchase, and there are paid subscriptions available for additional benefits, including access to a database of designs and drawings. The Glowforge is also equipped with a built-in camera, enabling precise alignment of your design with the material in the machine. This combination of web-connected control and a built-in camera enhances the user experience, making it more versatile and convenient.

The Glowforge success story began in 2015, when the project was funded via Kickstarter with great success. There are now three different versions of the Glowforge on the market:

Glowforge Plus : This version uses a 40W CO2 glass laser and has an editing area of 49.5 x 27.9 cm

Glowforge Pro : Featuring a 45W CO2 glass laser and the same machining area as the Plus version, the Pro also offers a convenient pass-through door that allows longer objects to be loaded.

Glowforge Aura : Also known as the Craft Laser, this version uses a 6W diode laser with a processing area of approximately 30x30cm.

The Glowforge is a versatile and innovative laser cutter ideal for a wide range of creative projects. Whether you're working with wood, cutting acrylic, or crafting unique jewelry, the possibilities are limitless with the Glowforge laser cutter.

What are Proofgrade materials?

Proofgrade materials are a selection of 36 different materials specifically intended for use in the Glowforge laser cutters.

These materials are guaranteed suitable for laser cutting and are precisely tailor-made for the Glowforge.

The handy thing is that you can order these materials in small quantities, directly from Glowforge itself.

In addition, the Proofgrade materials are provided with a QR code, so that the Glowforge automatically recognizes the materials and selects the correct settings.

What materials can you buy at Lasersheets?

Lasersheets presents a thoughtfully curated selection of materials specifically crafted for laser cutting. These LaserGrade quality materials ensure a flawless cut with a laser. Available in various convenient sizes, there's always a suitable option for every laser cutter. Ordering these materials is a straightforward process, and you can easily do it online, starting from just one piece.

Lasersheets materials are not just perfect for various creative projects but are also well-suited for professional applications. Additionally, Lasersheets offers a specialized range tailored for schools, fablabs, and makerspaces, ensuring that you can provide your students and users with materials that meet their needs. The use of high-quality Lasersheets materials guarantees optimal results when laser cutting.

What should you pay attention to when purchasing materials for your Glowforge:

The right dimensions

It is important that the materials you purchase fit your Glowforge laser cutter.

- If you have a Glowforge Plus or Pro, choose materials with a size of 20x30cm or 50x25cm .

- If you have a Glowforge Aura, choose materials with a size of 20x30cm or 16x25cm .

In wood, the grains run parallel to the long side of the board. Read more on this page .

The right thickness

It is also important that the materials are not too thick . The laser power of your Glowforge determines the maximum thickness you can cut. The next part of this blog post describes in detail which materials are and are not suitable for cutting with the Glowforge.

Which materials are suitable for your Glowforge?

To help you get started, we have listed which materials you can cut. For each material you will see the maximum thickness you can cut, or a red cross if it is too thick for your machine.

Note: While it may be possible to cut thicker materials, such as 6mm black MDF, by making multiple passes along the same line or cutting extremely slowly, we advise using materials that can be cut in a single pass at a reasonable speed. This not only yields the best results but is also the safest approach.

| Materials suitable for the glowforge |

Maximum thickness for cutting

|

|

| Glowforge (pro) | Glowforge Aura | |

| Wood: | ||

| MDF | up to 6mm | up to 3mm |

| Black MDF | up to 3mm | up to 3mm |

| Veneered MDF 4mm | up to 4mm | ✘ |

| Birch plywood | up to 4mm | up to 3mm |

| Bamboo side pressed | up to 5mm | ✘ |

| Poplar plywood | up to 6mm | up to 6mm |

| Cardboard: | ||

| Corrugated cardboard | up to 3mm | up to 3mm |

| Museum cardboard | up to 2mm | up to 2mm |

| Felt cardboard | up to 1mm | up to 1mm |

| Laser board | up to 0.5 mm | up to 0.5 mm |

| Plastic: | ||

| Acrylic | up to 6mm | up to 3mm |

| Engraving sheet | up to 3.2mm | up to 3.2mm |

| Mirror acrylic | up to 3mm | up to 3mm |

| PETG (Polyester/Vivak) | up to 0.8mm | up to 0.8mm |

| PE rigid foam | up to 5mm | up to 5mm |

Materials to avoid with the Glowforge laser cutters

Prevent problems and discover which materials to avoid when using the Glowforge laser cutter.

PVC

PVC, or polyvinyl chloride, is a widely used material known for its versatility and durability in various applications, including the production of vinyl records. However, it's crucial to note that laser cutting PVC is strongly discouraged. When PVC is heated during the laser cutting process, it releases toxic fumes such as chlorine gas, posing a health risk even in small quantities. It's important to emphasize that relying solely on a good filter installation is not sufficient protection against these harmful gases.

Fortunately, there are alternative materials that can be used safely with the Glowforge laser cutter. Some popular alternatives to PVC are acrylic. Acrylic is a versatile material that is easily cut with the Glowforge laser cutter and does not emit toxic fumes.

Polycarbonate

Polycarbonate, also known as lexan, is a resilient plastic commonly employed as a glass alternative due to its impact resistance. While it can be found in hardware stores, attempting to laser cut polycarbonate will reveal that the machine struggles to cut through it, and the cut edges tend to burn brown, generating a substantial amount of smoke. Polycarbonate is a thermoset and is not suitable for laser cutting. Once again, acrylic proves to be a suitable alternative. It is crystal clear, sturdy, and possesses weather and UV resistance.

Plywood or MDF with the wrong glue

Many types of plywood and MDF contain glue that is not suitable for laser cutting. If you try to laser cut it, the material will burn and the edges will become black and sooty, or you will not be able to laser through it at all. There are also often knots in the inner layers that the laser cannot cut through. Our wood types are laserGrade , which guarantees that they are suitable for laser cutting.

Plastics of which you do not know the type

Many plastics contain harmful substances. You shouldn't take that risk.

Sky (imitation leather)

Faux leather, also known as sky, is a popular material often used to make clothing, bags and other accessories. It has the look of real leather, but is made of synthetic materials including PVC. As you have read above, this is one of the materials that you should absolutely never cut with your laser due to the health risks.

Thick materials

It's advisable to steer clear of materials that are overly thick when using the Glowforge. While some individuals may achieve success with "multiple passes," cutting the same line multiple times, we do not recommend this approach. The outcomes tend to be less aesthetically pleasing, and there is often an increased risk of a fire hazard in your laser cutter. This is due to the gases released during the cutting process, which may not be adequately removed, lingering above the material. Optimal results are typically achieved by using materials that can be laser cut in a single pass at a reasonable speed.

What is too thick a material for your Glowforge? This varies per material, but in general the following applies: the less the material weighs, the thicker you can cut it. You can easily experiment with this yourself. Use the table above as a starting point.

Safety and your Glowforge

long when using the Glowforge laser cutter. After 12 years of experience, here are our top tips for working safely with your laser:

1. Always cut with the hood closed: It is essential to always keep the hood of the Glowforge laser cutter closed during the cutting process. This ensures that any reflected laser beams are blocked and that fumes are neatly extracted.

2. Never work without good extraction: Good extraction is crucial to remove fumes and smoke while cutting. This can be done using a carbon filter or by extracting the flue gases outside. It is also important to ventilate the work area well, because when you open the hood, some residual smoke always comes with it. After cutting, it is advisable to wait a few seconds before opening the hood.

3. It is important to only cut materials whose composition you know and which are suitable for laser cutting. Some materials can release toxic fumes when heated, such as PVC. It is therefore essential to have sufficient knowledge about the materials you use to avoid health risks.

4. Never walk away from a laser that is working. It's tempting, because the machine works by itself. But running away can be dangerous as there is always a risk of fire. Always stay near the laser and supervise the cutting process.

5. Have a fire extinguisher on hand: Although unlikely, a fire can always occur in the laser. You should therefore always have a fire extinguisher within reach. If we respond quickly, worse can be prevented.

6. Ensuring proper maintenance of the machine is crucial. It's essential to adhere to the manufacturer's specifications for regular maintenance, which includes keeping mirrors and lenses clean to optimize the functioning of the laser beam. Additionally, maintaining the proper alignment of the laser is important to uphold cutting quality consistently. Regular and thorough machine maintenance helps to achieve optimal performance and extends the lifespan of the equipment.

By observing these safety measures, you can work safely and efficiently with the Glowforge laser cutter. It is important to always take the proper precautions to ensure the health and safety of yourself and others.

Tips for best results with the Glowforge laser cutter

Get the most out of your Glowforge laser cutter with these helpful tips.

Settings and speeds

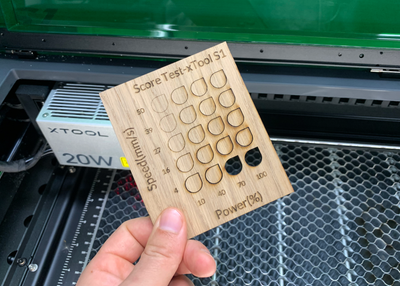

Understanding how to achieve the best cutting results with the Glowforge laser cutter is crucial when working with various materials. Employing the right settings and speeds ensures that your projects are cut precisely to your specifications.

First of all, it's important to know that settings and speeds may vary depending on the material you're using. Each material has its own properties and may require specific adjustments.

When adjusting the cutting settings, it is advisable to first make a test piece. This allows you to adjust the settings without the risk of ruining an entire project. Start with the laser power at maximum and low speed and gradually increase it until you achieve the desired result.

Another factor to consider is the focus setting. The laser beam must be optimally focused to achieve the best cutting results. Make sure the focus is set correctly for the material you are using, as incorrect focus can lead to inconsistent cuts and burnt edges.

Through experimentation with various settings, speeds, and careful consideration of focus and cutting techniques, you can attain optimal cutting results with the Glowforge laser cutter. While it might take some time to discover the best settings for each material, patience and practice will enable you to produce beautiful projects.

To test

An important tip when working with the Glowforge laser cutter is to always test small pieces of your design before undertaking the full project. This is especially useful when you have parts that need to fit together. By testing small pieces you can ensure the fit is perfect before cutting the entire project.

Resources

Read our blog on getting started with laser cutting for 10 must-have websites for laser cutting, or learn how to create a halftone work of art from your favorite vacation photo.

Finally

The Glowforge machines are the perfect lasers for designers, makers and anyone who wants to create creative work. With Glowforge's user-friendly and simple controls you can effortlessly create the most beautiful projects. And if you also use the right materials, the possibilities are endless!