Are you looking for the ultimate diode laser experience? Do you want to know whether the Xtool S1 20W is the perfect match for your projects? As laser-cutting experts, we accepted the challenge and tested the Xtool S1 20W extensively. Do not expect sponsored praise here, but an honest review based on our own experiences. From unboxing to the final engraved details, we share everything you need to know about this diode laser. Are you curious to hear our conclusions? Just read on here!

Xtool is one of the common brands in Europe. There are two basic diode laser models to choose from, namely the S1 and the D1. The largest difference is the external case. Unlike the D1, the S1 is produced with a closed case, for example, which gives the machine a much more professional appearance. It also boasts improved basic properties, such as safety in use, because of the tinted glass in the protective hood and the internal smoke extraction. These features are the main reasons we chose to invest in the Xtool S1.

In terms of power, both machines are available in similar modules:

- Xtool D1 is available in 5, 10, 20 and 40 watts.

- Xtool S1 is available in 10, 20 and 40 watts.

The S1 20W appears to be a nice medium and it is also suitable for most materials and thicknesses we offer in our shop. A 40-watt module seems a bit excessive, because it is considerably more expensive and still does not have the advantages of a CO2 laser cutter.

Read on for our honest review of the Xtool S1 20W.

Unboxing and quick setup

Unpacking and installation of this laser cutter is very easy and takes around 30 minutes. The S1 is packed securely and arrives almost fully assembled. Basically, all you have to do is attach the laser head, connect the cables and install the air exhaust. This is explained step by step in the accompanying brochure. This brochure can also be found online, on the Xtool website. It is good to mention the length of the supplied air exhaust hose here, as it is only 1500 mm in length. This limits your placement options.

Software

XCS

The Xtool is controlled with the associated software XCS (Xtool Creative Space). XCS works intuitively and has a simple and clear interface. It can also control the laser cutter via USB, when there is no internet connection available. Our favourite feature is the ‘Material Test Array’. This is a function with which you can create a ‘score’; a grid of cut or engraved shapes, each with a different setting. That way, you can find the perfect settings for cutting or engraving for any kind of suitable material.

Through XCS, users are able to set the position of the laser module precisely, as well as mark processing areas, and even process curved materials. One of the standout features of the Xtool S1 is the excellent autofocus feature. By using the pinpoint-method on the surface of the material, the laser is able to focus accurately, even on bent surfaces.

Lightburn

Even though the Xtool S1 is compatible with Lightburn, a commonly used general-purpose software for controlling lasers, we prefer to stick to XCS. That is because Lightburn currently only supports the basic features of the Xtool S1, with limitations and bugs in the advanced features. For example, accurate positioning of the laser module is not supported, and it also does not read materials with a curved surface as well as it should.

Safety

Housing

The sealed case ensures a safe working environment, particularly when the machine is set up at home and not at a workshop. Pets and other family members are not inconvenienced by it, which is nice. You can only use the laser when the protective hood is closed. This hood is made out of coloured glass, which enables you to peek into the machine safely whilst in use. We still do not recommend doing this continuously.

Air extraction

The air extraction does not work perfectly, as the built-in ventilator is relatively weak. We ordered the Smart Air Assist at the same time. Unfortunately, it will be delivered afterwards, and we have therefore not been able to test it yet. The Smart Air Assist should minimise smoke stains on the surface of the material that is being cut. In need of a temporary solution, we used compressed air as an alternative. This actually also works fine and the cuts are reasonably clean.

Fire

To detect fire, two sensors have been installed. When these are activated, the machine turns itself off automatically. This sensor activates rather quickly, as we found out when cutting thicker plastics such as polyacetal and acrylic. Should you notice an unsafe situation sooner, then you can immediately turn off the machine with the red emergency button, positioned at the rear right side of the machine.

Possibilities

Materials

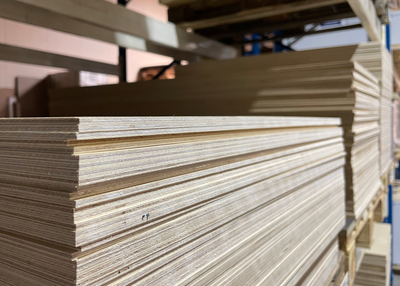

The power of the Xtool S1 20W diode laser does not disappoint. It performs surprisingly well on different materials, such as bamboo, plywood, MDF, veneered wood, various plastics, cardboard and foam. Whether you want to engrave beautiful decorative items, cut prototypes or small products; this machine handles it all very well.

Fine precision and detail

What really stands out, is the precision with which this machine works and this actually surprised us. Small fonts, detailed patterns; it all comes out razor sharp. Reproduction is also good. The result remains the same, as long as the lens is cleaned in between.

Autofocus and depth control

The S1 is equipped with a fine autofocus system which automatically calculates the optimal focus distance for the material that you want to work with. This ensures consistent and accurate results, even on materials with uneven surfaces.

Work area

With a work area of 498 mm x 330 mm, the Xtool S1 offers sufficient space for processing reasonably large pieces of material. However, the machine itself does not take up too much space, making it easy to put away.

User-friendly software interface

Finally, the software interface is really user-friendly. Whether you choose the XCS software of Xtool or Lightburn, you can get started quickly without a lengthy learning curve. XCS is a bit simpler and supports slightly more functions, however.

Comments

- The slats used to create a raise for cutting the material are supplied with the S1 as standard. They can be replaced by a honeycomb which needs to be ordered separately. We can definitely recommend this, because we are not exactly a fan of the slats. They shift easily and with smaller pieces of material you have to be careful not to laser into them.

- Cleaning the lens is a bit of a hassle. You have to allow 15 minutes for this, because the laser module needs to be completely disconnected.

- The ventilator for the extractor van cannot be controlled as a parameter in the Creative Space, is not very powerful, and the extraction hose supplied is of a limited length.

- Positioning the emergency button at the front of the machine would be better, because it gives you better and faster access.

- On top of that, there are the standard limitations of a diode laser that are not unique for the Xtool S1, such as the inability to laser blue or transparent material.

Conclusion

Because of our 12 years of experience with laser cutting we have a very critical view on equipment. The Xtool S1 20W and the XCS programme managed to pleasantly surprise us. The machine and the software are thoughtfully designed and almost everything works intuitively or can be learned quickly. All in all, we think that the Xtool S1 20W is an excellent choice for both beginners as well as experienced laser cutter fans.