Filter and sort

13 products

You should know this about wood sheet material for the laser cutter

Edit wood plate material in the laser cutter will yield your beautiful results. It is therefore one of our most popular categories with our customers. We sell different types of thin wooden sheets From 2 mm thick, but also with a thickness of 0.5 mm, 1 mm, 3 mm, 4 mm to 12 mm. They are all laserGrade, In other words, especially suitable for use for laser cutting or engraving.

With wood sheet material you make everything, from jewelry to musical instruments and from furniture to toys. If you treat wood with varnish or oil, it can also be used outside. Read more about this versatile material and the wooden sheets From the range of Lasersheets.

We sell our wood plate material from one sheet To the great edition. In the latter case you get an interesting scale discount.

Did you know that ... Lasersheets Also FSC® Mix Credit Birch PLIPPLEX and FSC® MIX 70% MDF sheets sells?

Different types of wooden sheet material and their properties

With us you can come for different types of wood plate material. We sell MDF (standard, veneered, and through black and white coated), plywood (birch and poplars) and solid wood (bamboo). These are available in a number of different thicknesses and dimensions.

Each material has different characteristics and advantages and disadvantages. To help you choose your ideal material, we discuss them here in detail.

1. MDF

MDF stands for Medium Density Fibroard (or Fiberboard). These sheets From pressed and glued wood fibers. For the MDF sheets by Lasersheets Is only las -friendly interior glue used, so that they perfectly come out of the laser cutter. MDF sheets are strong, stiff and very cheap. You use them for projects that still need finish, but you can also use them without painting or treating it.

The thin wooden MDF sheets From 2mm are particularly strong for their thickness and even with low power lasers can still be cut. Because it is cheap, and strong, and very easy to laser cut, it is one of the most used materials For laser cutting. Of course we also have other thicknesses in stock.

Because MDF is versatile, it is used for all kinds of different applications, including:

- Interior projects

- Furniture construction

- Models

- Stencils

The range of MDF wood plate material at Lasersheets Is great. Here you will find the different options that we offer, including the thicknesses and sizes from which you can choose.

Standard MDF is one of our most popular materials. We sell the thin wooden MDF of this sheets of 2 mm. This MDF has no finish, so you have complete freedom to realize your own appearance.

- Dikes: MDF 2 mm, MDF 3 mm FSC® Mix 70%, MDF 4 mm FSC® Mix 70%, MDF 6 mm FSC® Mix 70%and MDF 9mm FSC® Mix 70%.

- Dimensions: 20 x 30 cm, 60 x 30 cm, 60 x 60 cm, 90 x 60 cm, 120 x 60 cm.

Oak, nuts and ash is an MDF sheet With real wood veneer on both sides. This way you have a beautifully finished sheet With natural appearance, ideal for interior applications, product displays and modeling.

- Thickness: MDF 4 mm.

- Dimensions: 20 x 30 cm, 60 x 30 cm, 60 x 60 cm, 90 x 60 cm, 120 x 60 cm.

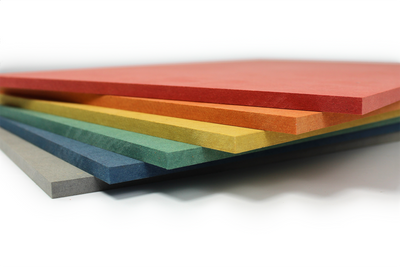

Black MDF has a black color that throughout sheet has been applied. So it is not a black coating, but colored through and through. Use it for furniture, enclosures, speakers or signing. It is heavier and slightly stronger than standard MDF. It can also be a little better against water than usual MDF, although you have to coat it in damp environment before use.

- Dikes: MDF 3mm and MDF 6 mm.

- Dimensions: 20 x 30 cm, 60 x 30 cm, 60 x 60 cm, 90 x 60 cm, 120 x 60 cm.

White coated MDF is equipped with a decorative top and bottom layer. The characteristics are the same as from standard MDF, but finish is no longer necessary. With your laser you can engrave through the coating, causing the wood to be exposed. This gives a nice contrast and a unique look. Use it for cards, jewelry, furniture or enclosures.

- Thickness: 3 mm.

- Dimensions: 20 x 30 cm, 60 x 30 cm, 60 x 60 cm, 90 x 60 cm, 120 x 60 cm.

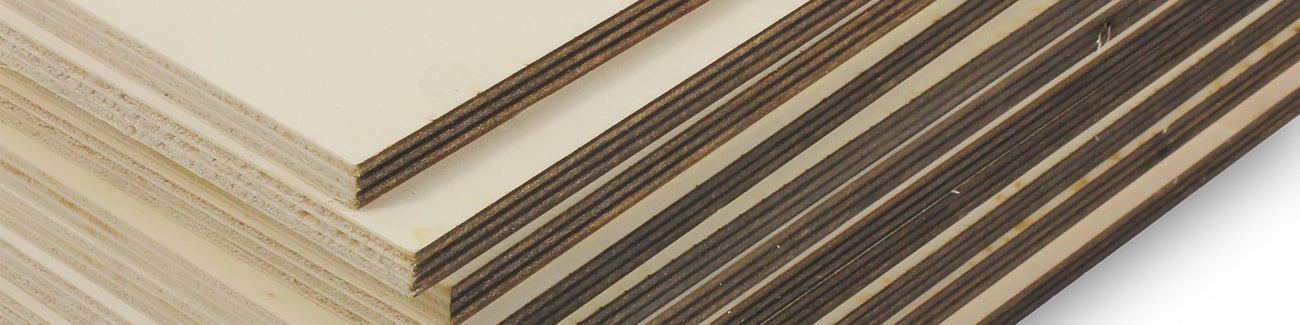

2. Plywood/plywood

Multiplex, plywood and aircraft carpet do not consist of glued and pressed fibers, but are made up of several wood venal layers. Because these crosswise are glued together, they are strong in all directions. That makes them better suited for many projects than solid wood, because plywood sheets Less break.

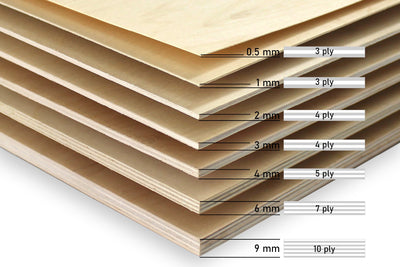

The terms aircraft triplex, aircraft plywood, plywood and plywood are about the number of layers and thickness. Aircraft triplex is a term used for thin plywood or plywood sheets from less than 3 mm.

Normal aircraft cyclex, however, is not suitable for laser cutting. Normal aircraft triplex is difficult to cut and gets black, soety edges that give off. That is because normal aircraft triplex is glued with exterior glue (after all, it was meant for use in aircraft). Our thin plywood is not bothered by that, because all types of plywood that we sell are made with laser-compatible glue.

Triplex means that the wood is made up of three layers, and plywood that it is made up of more than 3 layers. In practice, the terms are used interchangeably.

Keep in mind that plywood and plywood sheets have a head grain direction. This runs as standard in the length of the sheet, Except with the 600x400 format sheets. There, the main grain direction runs across the sheet. Read more here About dimensions and grain direction. Of course the plywood and plywood have sheets by Lasersheets A glue that is suitable for the laser cutter.

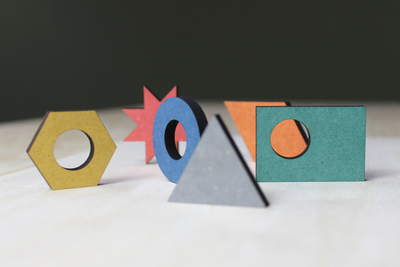

Multiplex is used in the laser sector for all kinds of applications:

- Model

- cards and jewelry

- Home Decoration

- Furniture construction

- Boxes and housings

With us you have the choice of birch plywood and poplar plywood. The difference between these two wooden sheet materials is not only in the appearance, but also in the characteristics.

Us Birch plywood Comes out Sustainably managed forests in Europe. We always look for the most sustainable options and a number of thicknesses are FSC® certified (see below). Birch is strong, beautiful, of course and has a clearly visible grain.

- Thickness: birch airplane triplex 0.5 mm, birch airplane triplex 1 mm, birch airplane triplex 2 mm, birch triplex 3 mm FSC® mix credit, birch triplex 4 mm, birch multiplex 6 mm fsc® mix credit, birch multiplex 9 mm.

- Dimensions: 20 x 30 cm, 60 x 30 cm, 60 x 60 cm, 90 x 60 cm, 120 x 60 cm.

Populier Multiplex Is, in contrast to birch plywood, a bit softer. It is also lightweight. That makes it an excellent choice if you want to cut thicker wood sheet material with your laser. With a good 90W laser, for example, you can already cut 12mm thick poplex plywood. The thicker sheets Are very strong because they have many thin layers of quality wood.

Our poplex plywood is from Ecoplex. It is of high quality, brush -free and beautiful light in color. It is a sustainable option, because poplar wood is, unlike some other tree species, a quick growth. At Ecoplex themselves they guarantee sustainability to perfection.

Poplex multiplex is used in model building because it is so lightweight. But it is also suitable for making furniture, art installations, (ship) models, etc.

- Thickness: Poplex plywood 6 mm, Poplar plywood 10 mm, Poplar multiplex 12 mm.

- Dimensions: 20 x 30 cm, 60 x 30 cm, 60 x 60 cm, 90 x 60 cm, 120 x 60 cm.

Solid wood

Are you looking for wood plate material with a luxurious look? Then our solid wood (bamboo) is a must. This sheets are made of long bamboo fibers that have been compressed. They consist of 100% solid wood and have a very natural appearance.

Bamboo In addition to our FSC® certified wood and poplar plywood, is also a sustainable choice. Bamboo grows very fast and every trunk used is therefore quickly replaced. The outer layers of the bamboo battle are glued together, resulting in a hard and smooth one sheet.

Note: solid wooden sheet material is beautiful, but is sensitive to fractions along the veins. It is extremely strong across the veins. So don't make designs of bamboo too thin, then you prevent it from breaking.

Our bamboo solid wooden sheets are widely used for front panels, displays and enclosures.

- Thickness: solid wood 5 mm.

- Dimensions: 20 x 30 cm, 60 x 30 cm, 60 x 60 cm, 90 x 60 cm, 120 x 60 cm.

How can you edit wood plate material in the laser cutter?

Many of our customers choose thin wooden sheets From 2 mm thick or even less for use in the laser cutter. You can do and make everything with that. You can even cut this with lower power lasers like the glowforge Or diode lasers. There are one Large number of websites With ideas and ready-made vector files for use in your laser cutting machine.

How can you edit wood in your laser cutter? Our wood sheet material and thin wooden sheets of 2 mm are ideal for:

- Laser cutting (make a box, a kitchen cupboard or parts for model building).

- Engraving (engraving a photo, sketch or logo in the wood for a natural and stylish result).

- With Halftone you can turn a photo into an image that consists of Thousands of holes of different dimensions.

Tips for the purchase of wooden sheet material

Bee Lasersheets Do you have the guarantee that the sheet material is perfect for laser cutting. That of course does not alter the fact that you can also use it in other ways. Because the choice is large, we share our tips so that you buy the best wood for your purposes. Do you have any questions? Then of course you can always come to us for specialist help with your choice.

1. Avoid plane triplex

If you are looking for a thin wooden sheet From 2 mm, then you will undoubtedly come across the term "aircraft triplex". It is often used for plywood sheets Those thinner are then 3 millimeters. That sounds ideal, but real aircraft triplex is glued waterproof, which is not ideal for your laser cutter.

So we recommend avoiding aircraft triplex and only this plywood sheets To be used with a las -friendly glue. So are all our sheets glued with interior glue, which does yield good results.

2. Wood sheet material cannot be used outside just like that

Acrylate is a material that is suitable for outside and inside, but that is not wood sheet material. This must first be finished before it is weather, UV and moisture resistant. That is important if you use it for, among other things, signs or garden furniture.

sheets For outdoors from the hardware store, glued with waterproof glue, making them less suitable for laser cutting, just like aircraft triplex. For example, you can use the wooden sheet material watertight with stain, lacquer or varnish.

Note: Wood plate material that stands outside a lot must be regularly maintained and treated again. This way it stays beautiful for longer and you prevent dehydration, fungal formation and rotten.

3. MDF wood is the easiest in the laser cutter

Because MDF sheets Being homogeneous and nowhere to be knotted or contain natural differences, it is an easy material for laser cutting. Once you have determined the right settings, the cutting is actually always going well. With natural wood, especially low -quality plywood, it can sometimes happen that there are knots in the wood. Sometimes they are in the outer layer and you can see them, but it is also possible that there are knots in the inner layer that you do not see on the surface. Noes are of a much harder type of wood and many lasers have difficulty cutting through it. At least not with the same settings with which you can use the rest of the sheet cuts. It is therefore advisable to use the highest possible quality plyplex with little hardy if you go laser cutting.

4. Do you want to know more how you can save costs when purchasing sheet materials?

You can read that in this blog.

Lasersheets For all your wood plate material

All the wood we sell, from thin wooden sheets From 2 mm to poplex plywood of 12 mm, has been carefully selected for the laser cutting machine. Our customers consist of hobbyists, designers, entrepreneurs, technasiums, fablabs and producers. We offer all materials To in small and large editions and we ship by mail or on small pallets, so that you can also receive it in a smaller workshop.

Because we have 12 years of experience with our sister company Snijlab We are 100% behind all information on this website and the quality of the materials. So view our extensive webshop. When in doubt, contact us so that together we choose your ideal wood plate material. Because laser cutting is our passion and specialty.