A warped piece of wood can ruin your entire project. It's a waste of money and frustrating if you can't create something beautiful with your laser cutter. Flat wood is essential for laser cutting. But wood is also a natural product and comes in many different qualities. We have 15 years of experience with laser cutting and have tried many different types of wood over that time. In this blog post, we explain what to look for when buying wood and where to find flat wood for laser cutting.

What makes wood unsuitable for laser cutting?

Not all wood is safe or pleasant to laser cut. Besides warping, you can also encounter problems with the quality of the wood. Consider, for example, the number of knots. Furthermore, the gluing of plywood can cause excessive soot formation, and some types of MDF contain toxic formaldehyde.

Warping

Wood that warps excessively is unsuitable for laser cutting because the laser beam becomes unfocused. Machines with autofocus can sometimes still process these panels. Internal panel tension warps the wood when humidity changes. Sometimes you can prevent warping by storing panels flat, wrapped, and under a weight.

Incorrect bonding

Plywood is an excellent material for laser cutting: the layers allow the laser beam to penetrate evenly, making it sturdy. However, adhesives are often used that produce a lot of soot. Soot is not only annoying because it takes time to sand away, but it's also bad for your machine and smoke exhaust. There's a sheet-metal bonding solution specifically for laser cutting that produces less soot. This extends the life of your machine and saves rework time.

Toxic substances

MDF generally contains formaldehyde, which is released during laser cutting. This is a toxic substance, harmful to humans and the environment. Therefore, this type of MDF is not suitable for laser cutting. There are also MDF variants with little or no formaldehyde, which are suitable.

Knots and repair pieces

Knots are a nuisance in laser-cut wood. Their density and hardness differ from the rest of the panel. As a result, they react differently to the laser: they create extra soot or are difficult to cut. With plywood, you can't see how many knots are inside. Therefore, pay attention to the wood quality. This is determined according to standards such as NEN 5466, which consider distortion, cracks, and knots. Pine, for example, is classified into classes A through D. Class B is known as 'construction wood': strong, straight, with few knots, and kiln-dried. This quality is ideal for visible work and produces clean, consistent cutting results.

At Lasersheets, we consider all these aspects. Below, you'll find a table comparing our wood types.

Where do you buy flat wood for laser cutting?

Wood is available in many places. What are the pros and cons of these options?

DIY store

The hardware store seems like a logical place, but it's rarely ideal. Panels are often stored upright, causing them to warp. Moreover, the wood is usually not glued for laser cutting, which produces a lot of soot. It can also contain many knots or repair pieces. Therefore, it's not designed for precise laser cutting.

Timber trade or wholesaler

Here you'll find high-quality panels in various qualities and beautiful finishes. However, this is often not accessible to private individuals. Wholesalers sometimes only accept business customers, have minimum order quantities, and only supply large-format panels.

Specialty stores for model building or veneer

These stores can be difficult to find, but they often offer high quality. If you're looking for good wood, you've usually come to the right place.

Laser sheets

At Lasersheets, you'll find laser-ready wooden sheets in sizes that fit your machine. You can order from just one piece. Looking for quality wood for your laser? Then you've come to the right place. The LaserGrade quality mark indicates which laser source you can use to cut a sheet.

What is different about wood for laser cutting?

Wood specifically intended for laser cutting has the following properties:

-

Safe bonding: less soot formation and harmful fumes.

-

Selected for flatness and minimal internal stress.

-

Free from knots and repair pieces for a more consistent cutting result.

-

Handy formats, tailored to common laser cutting machines.

This makes laser cutting wood not only safer, but also more efficient to use.

Why did Lasersheets develop wood specifically for laser cutting?

Lasersheets is a subsidiary of Snijlab, a well-known laser cutting service in the Netherlands and Belgium for 15 years. We cut large quantities and complex designs in wood and plastic every day. Poor quality materials mean product failure, lost time, and frustration – we can't afford that.

We continuously monitor the market and have selected the best materials over the years. If we can't find the right quality, we have it custom-made: with safe adhesives and a tight construction. We rigorously test every material. This guarantees consistent quality and minimal waste. We sell these materials through Lasersheets, directly from our warehouse. This way, we help other makers, schools, and businesses obtain the right materials.

Which wood warps easily?

Wood warps when it contains internal stresses or is exposed to fluctuations in humidity. Storing or shipping upright can also cause warping.

European birch plywood, 3 mm thick, is popular for its strength and attractive appearance, but it warps relatively quickly. This is due to internal tension in the thin sheets and their sensitivity to humidity. Thicknesses of 6 mm and above are more stable and maintain a flat surface.

What helps against warping?

-

Always store wood flat, preferably with a weight on it.

-

Allow wood to acclimatise in the space where you will be working.

-

Is a panel warped? Cut it into smaller pieces to relieve the tension.

Read more about warping in: Help, my birch wood is warping!

Which types of wood remain flat?

-

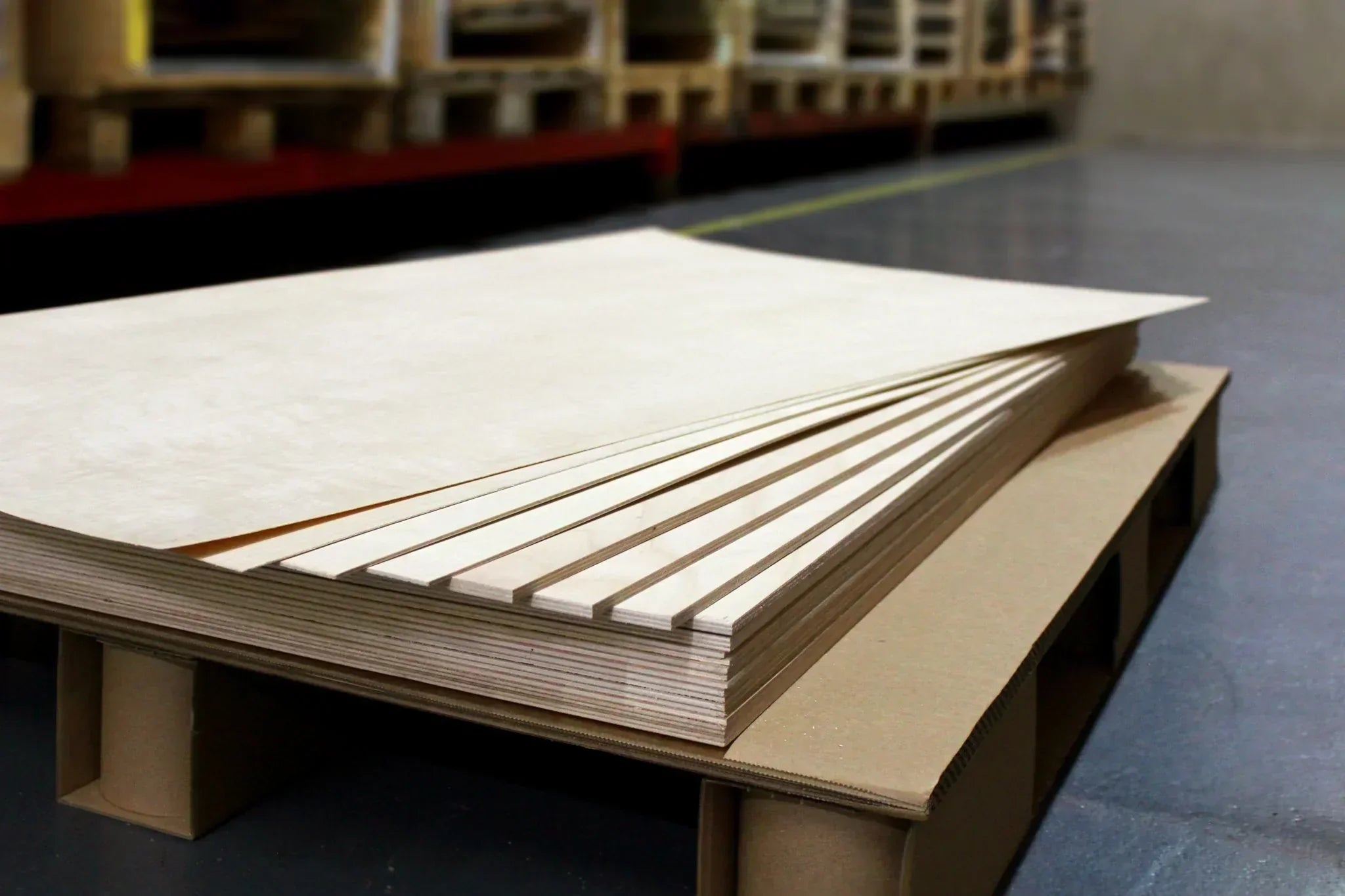

Linden plywood

Lightweight, easy to cut (even with diode lasers), evenly colored, and specially bonded. Very flat and clean cutting results.

-

Asian birch plywood

More stable than European birch. Less internal tension, specially glued, few knots, high quality.

-

Veneered MDF

MDF with a real wood veneer. Luxurious appearance, easy to cut, and available in various wood types.

These materials are popular with designers, schools and makers who need reliable materials.

Just starting out with diode laser cutting? Check out our starter kit for diode laser cutters.

Our top recommendation: the Lindemultiplex Advantage Package

The Linde Multiplex Value Pack is ideal for those looking for reliable, flat material. The panels are super-flat and deliver a smooth, flawless finish. Its light weight also makes this material suitable for diode lasers and smaller machines.

You can order the package directly from stock in sizes that fit your laser. You don't need to order large quantities: you can order from a single package. Thanks to the bundle price, you'll save money compared to individual plates.

We hope this blog is helpful in your search for laser equipment. Want to learn more about our materials? Feel free to visit our showroom or contact us.